In industrial production, Cut Off Blade is one of the essential tools in the process of cutting and dividing materials. Choosing the right Cut Off Blade not only improves productivity, but also ensures cutting accuracy and quality and extends equipment life.

1. Understanding Production Needs

Before selecting a Cut Off Blade, it is important to understand the specific needs of your production. Different processes require different types of blades. Considering the following factors is the basis for selecting the right blade:

Who you're cutting: Blade selection depends on the type of material, such as metal, plastic, wood or other composite materials. Different materials have different hardnesses and properties, and therefore need to be matched with the right blade material and design.

Cutting method: Is the cutting a manual, semi-automatic or automated operation? Each type of operation requires a different blade design and durability.

Cutting accuracy: According to the requirements of cutting accuracy, the design details such as tooth shape, thickness and edge angle of different blades are selected.

Production efficiency: for large-scale production, the wear resistance and cutting speed of the blade is particularly important, and you need to choose a blade with a long service life and high cutting efficiency.

Defining these needs can help narrow down the choices and find the Cut Off Blade that's right for the job.

2. Consider Material Characteristics

Different materials have different requirements for blades. The selection of a Cut Off Blade for a production job is based on the characteristics of the material to be cut, and the following are recommendations for different materials:

2.1 Metallic materials

Metallic materials are usually hard and require the selection of blades with high wear resistance and hardness. Common blade materials include:

High Speed Steel (HSS): HSS inserts have high wear and heat resistance and are suitable for cutting medium hard metals such as steel, stainless steel and aluminum alloys.

Tungsten Carbide (Tungsten Carbide): Tungsten Carbide blades are harder, suitable for cutting high strength, high hardness metal materials, can provide longer service life and higher cutting accuracy.

2.2 Plastics and Composites

Plastic and composite materials are usually soft and prone to burr or melt when cutting. Selection should take into account the characteristics of these materials and choose blades with the following characteristics:

Low coefficient of friction: reduces heat build-up during cutting and avoids melting or deformation of the material.

Sharp edge: ensures a clean and neat cutting edge to avoid burrs.

2.3 Wood

The cutting of wood requires blades with good sharpness and wear resistance. For hardwoods and softwoods, blades of different designs should be selected:

Hardwood: requires a high hardness blade with larger teeth for better cutting of hard materials.

Softwoods: a blade with smaller, sharper teeth can be selected to ensure a smooth cut and minimize material waste.

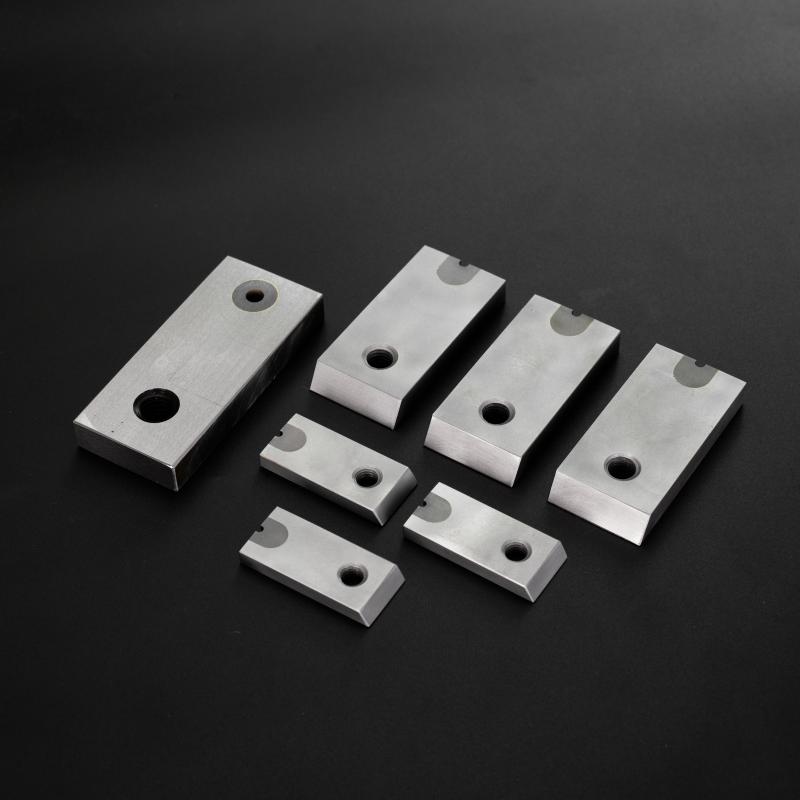

3. Blade Material Selection

The material of Cut Off Blade directly determines the cutting performance and service life of the blade. Different blade materials are suitable for different application scenarios. The following are some common blade materials and their characteristics:

3.1 High Speed Steel (HSS)

HSS has good abrasion and heat resistance and is suitable for cutting medium-hard materials such as steel, aluminum and plastics. HSS inserts are relatively inexpensive and are suitable for mass production where frequent changes are required. However, compared to tungsten carbide, HSS has a lower hardness and wears out faster when cutting high hardness materials.

3.2 Tungsten Carbide

Tungsten carbide inserts are extremely hard and wear resistant, making them suitable for cutting high-strength, high-hardness materials such as stainless steel, titanium alloys and other high-hardness alloys. Tungsten carbide blades have a long service life and are suitable for high-precision, high-efficiency cutting operations. Although more expensive, they are ideal in environments where high performance is required.

3.3 Ceramic Blades

Ceramic blades have extremely high hardness and corrosion resistance, making them suitable for cutting certain specialty materials such as glass, ceramics and other brittle materials. However, ceramic blades are brittle and prone to breakage in high impact cutting operations, making them suitable for specific low impact applications.

4. Choice of Blade Design

The design of the Cut Off Blade also affects its cutting performance, including design details such as tooth shape, edge angle, and blade thickness.

4.1 Tooth Design

The tooth design of the blade varies depending on the material being cut:

Coarse tooth blades: suitable for cutting harder and thicker materials such as metal or hardwood. The coarse tooth design improves cutting efficiency and reduces cutting resistance.

Fine-tooth blades: suitable for cutting soft materials or cutting that requires high precision, such as plastics, thin sheet metal, etc.. Fine-tooth blades can reduce burrs generated during the cutting process and ensure smooth cutting edges.

4.2 Edge Angle

The angle of the cutting edge determines the sharpness and durability of the blade when cutting materials. The larger the angle, the sharper the cut, but the durability is relatively low. A blade with a smaller angle will cut slightly less efficiently, but it will last longer and is suitable for continuous cutting operations.

4.3 Blade Thickness

The thickness of the blade affects the precision of the cut and the cutting speed. Thin blades are suitable for precision cutting, providing higher cutting accuracy and more detailed cutting lines; while thicker blades are more durable and suitable for high-intensity cutting operations.

5. Blade environment

The environment in which the blade is used is also an important factor to consider when selecting a blade. Different operating conditions can have a significant impact on blade performance.

5.1 Temperature

In a high-temperature environment, the blade is prone to thermal deformation, resulting in reduced cutting accuracy. Selecting a blade material that is resistant to high temperatures (e.g. HSS or tungsten carbide) can effectively counteract this problem.

5.2 Lubrication and cooling

In the cutting process, especially for metal materials, lubrication and cooling are important means to keep the blade sharp and prolong its service life. Selection of suitable lubricants and coolants can reduce blade wear and improve cut quality.

Choosing the right Cut Off Blade is a crucial part of the production process, directly affecting productivity, cost and product quality. Combining material properties, blade material, blade design and use environment and other factors, enterprises can choose the most suitable type of blade according to their own needs.