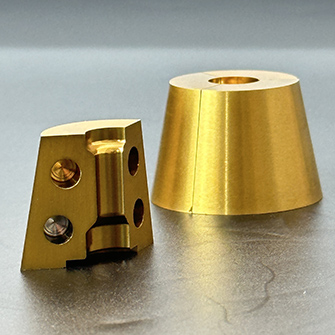

The Three-Piece Collapsible Mold is a specialized tooling system designed for precision casting, injection molding, and composite material forming. Characterized by its segmented construction and collapsible mechanism, this mold type enables efficient demolding of complex geometries that would be impossible with traditional Two-Piece Molds. The design consists of a base plate and two or more side segments that retract radially or vertically to release the molded part.

Key advantages include 30-50% faster cycle times compared to solid molds for complex parts, ±0.001 inch (0.025mm) dimensional tolerance maintenance across thermal cycles, and the ability to create undercuts without secondary operations.

Technical Specifications and Features

Modern three-piece Collapsible Molds incorporate several advanced features:

Segmented Construction: Typically manufactured from P20 steel (HRC 28-32), H13 tool steel (HRC 48-52), or aluminum (7075-T6) depending on production volume. The three-piece design allows for 5-15° draft angle reduction compared to two-piece molds.

Precision Alignment: Incorporates DIN 6341 standard guide pins with 0.0002 inch (0.005mm) clearance and self-lubricating bushings to maintain 0.002 inch (0.05mm) concentricity across 10,000 cycles.

Thermal Management: Designed with conformal cooling channels following 3D printed tooling standards (ISO/ASTM 52900) that reduce cooling time by 40-60% while maintaining ±2°F (±1°C) temperature uniformity across the mold surface.

Collapsible Mechanism: Utilizes cam-actuated or hydraulic retraction systems with 0.0005 inch (0.0127mm) repeatability and 10-50 ton clamping force capacity depending on size.

Surface finishes down to Ra 0.2μm (8μin) are achievable through precision machining and polishing, critical for optical-grade components.

Applications

Three-piece Collapsible Molds serve critical functions across multiple industries:

Aerospace Components: Manufacturing turbine blade prototypes with 0.003 inch (0.076mm) wall thickness and complex internal cooling channels. The collapsible design accommodates 15-25° undercut angles common in airfoil geometries.

Medical Device Production: Creating hermetic housings for implantable devices with ISO 13485-compliant surface finishes. The three-piece system prevents damage to delicate PEEK or UHMWPE components during ejection.

Automotive Lighting: High-volume production of polycarbonate lens assemblies requiring VDA 6.3 Grade A surface quality. The segmented design enables 90-second cycle times for parts up to 24 inches (610mm) in diameter.

Consumer Electronics: Molding unibody smartphone cases with 0.5mm wall sections and integrated button features. The collapsible action prevents >0.1% warpage in glass-filled nylons.

Industrial Components: Producing large-bore pipe fittings with NPT or BSPP thread forms in a single operation. The three-piece design maintains ASME B16.11 dimensional tolerances across 50,000+ cycles.

Maintenance Procedures

Proper maintenance ensures optimal performance and longevity:

Daily: Inspect guide pins and bushings for wear using 0.0001 inch (0.0025mm) resolution dial indicators. Lubricate with ISO VG 32 hydraulic oil or manufacturer-specified grease.

Weekly: Check retraction mechanism force consistency with load cells calibrated to ±0.5% accuracy. Verify cooling channel flow rates remain within ±5% of design specifications.

Monthly: Perform magnetic particle inspection (ASTM E1444) on steel components to detect microcracks. For aluminum molds, conduct dy penetrant testing (ASTM E1417).

Thermal Cycling: When processing materials with >300°F (149°C) melt temperatures, implement controlled cooldown rates of 50°F/hour (28°C/hour) to prevent heat checking.

Storage: Apply VCI (Vapor Corrosion Inhibitor) coatings and maintain 40-50% relative humidity in climate-controlled environments. Use shrink-wrap with desiccant packs for long-term storage.

Critical wear components like ejector pins and slides should be replaced after 100,000 cycles or when showing >0.0005 inch (0.0127mm) diametrical wear. Always follow OEM-recommended spare part specifications.

Operational Best Practices

To maximize mold performance:

Maintain 0.1-0.3% mold release agent concentration in water-based systems to prevent buildup while ensuring proper release.

Implement shot-to-shot process monitoring with ±0.1% pressure variation limits to detect early signs of component wear.

For glass-filled materials (>20% content), increase guide pin lubrication frequency by 50-75% to compensate for abrasive wear.

When processing engineering thermoplastics (e.g., PPS, PEI), preheat molds to within 50°F (28°C) of material glass transition temperature to prevent stress cracking.

Document all maintenance using digital mold history records tracking cycle counts, thermal profiles, and dimensional verification data.