Punch head mold, commonly referred to as "punching die head" or "punching die head" in Chinese, is a type of mold used to manufacture punching machines or punching machines. Its main function is to process metal plates or pipes into holes with specific aperture, hole spacing, and hole depth.Punch head molds are widely used in fields such as automotive manufacturing, aerospace, architecture, electronics, and furniture manufacturing. In these fields, Punch head molds are commonly used in machining processes such as punching, cutting, and slotting, and are one of the indispensable tools in mechanical manufacturing and processing.

Key Features

1. Material Selection:Punch Dies are usually made of high-strength steel or alloy to ensure wear resistance and stability for long-term use.

2. Precision machining:The molds need to be precision machined to ensure accurate size and shape of the holes or cut shapes.

3. Wear Resistance:Due to the large amount of pressure exerted on the mold during the stamping process, Punch Dies must have good wear resistance to extend service life.

4. Design Complexity:The design of the mold needs to take into account the thickness, shape and size of the material as well as the mechanical properties of the stamping process.

Areas of application

Punch Dies are used in a wide variety of industries, including:

1. Automotive manufacturing:used to produce automotive parts, such as body panels, chassis components, etc.

2. Electronic products:Used to manufacture shells, connectors and other components for electronic devices.

3. Home appliance manufacturing:used to produce the shell and internal parts of home appliances.

4. Metal processing:for the production of various metal parts, such as mechanical components, tools and instruments.

Manufacturing Processes

1. Design:Punch Die is designed according to product requirements, including the shape and size of the punch and die holder.

2. Machining:Use precision machine tools (e.g. CNC machining centers) to machine the die to meet the design requirements.

3. Heat Treatment:Heat treat the die to improve the hardness and wear resistance.

4. Assembly:The completed punches and die holders are assembled to ensure the precision of the fit.

Advantages and Challenges

Advantage:

1. Increased productivity:Can produce a large number of consistent parts quickly and efficiently.

2. High accuracy:enables the production of parts with precise dimensions and consistent shapes.

3. Cost-effective:suitable for high-volume production, helping to reduce the cost per part.

Challenges:

1. High initial investment:High cost of designing and manufacturing the Punch Die.

2. Maintenance:Regular inspection and maintenance is required to ensure the long term use of the die.

3. Design Complexity:Specialized knowledge and skills are required to design and manufacture accurate molds.

What are Punch Dies?

A punch die is a tool used for stamping, cutting, punching, and forming metal materials by mechanical or hydraulic pressure, and is widely used in manufacturing.

What are the main components of a Punch Dies?

A die usually consists of an upper die (Punch) and a lower die (Die). The upper die is used to apply pressure to cut or form the material, while the lower die provides support for the material and forms the desired shape or cut.

How does a punch work?

A die is punched, cut or formed by applying pressure from a punch press, which causes the upper die and lower die to move relative to each other, processing the material placed in the die.

What are the common types of dies?

There are various types of dies, including simple dies, composite dies, continuous dies, and multi-station dies, which are used for stamping tasks of varying complexity.

What are the common materials used for dies?

Dies are usually made of high hardness, high strength tool steel or tungsten carbide (tungsten carbide) to ensure wear resistance and long life for high frequency stamping operations.

How to maintain and care for punching dies?

Punching dies should be cleaned, lubricated and inspected regularly to avoid wear and corrosion. The edge of the die should also be regularly trimmed to ensure accurate cutting results.

What is the typical life of a die?

The lifespan of a die depends on the material it is made of, how often it is used and how well it is maintained. Typically, high-quality dies can withstand tens of thousands to millions of stamping operations.

What materials are dies used for?

Dies are suitable for processing a wide range of materials, including sheet metal (e.g., stainless steel, aluminum, copper), plastics, rubber, and composites.

How do dies affect machining accuracy?

The design and manufacturing accuracy of a die has a direct impact on the dimensional accuracy and surface quality of the machined part. A high precision die ensures consistent parts and reduces scrap.

In which industries are stamping dies widely used?

Punching dies are widely used in automotive manufacturing, electronic component production, appliance manufacturing, aerospace, and metal fabrication industries, where they are responsible for cutting, punching, and forming parts.

| Specification: | Custom |

| Customization: | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

| Product Material: | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

| Standard: | DIN ANSI BS JIS |

| Surface Treatment: | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

| Polishness: | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

| Tolerance: | +-0.002mm |

| Hardness: | Depends on material(HRC60~94) |

| Application: | Machinery Parts ,mold |

More Parameter Details | |||

| Place of Origin: | Dongguan, Guangdong, China | Brand Name: | Donglong, or your brand, it’s your choice |

Model Number: | Shaping Mode: | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling | |

| Product Material: | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect | Demension (Size): | Customized |

| Surface Treatment: | TiCNTiN, Aitain, Ticrnnitriding Black oxygened Black coating etc available | Application: | Machinery Parts ,mold |

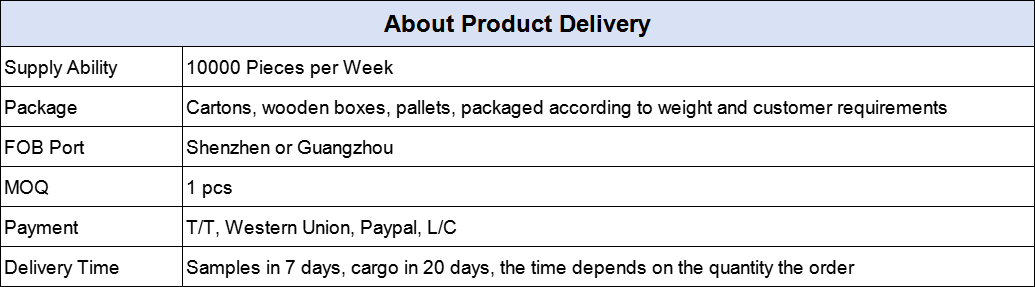

| Supply Ability: | 10000 Pieces per Week | Package: | Cartons, wooden boxes, pallets, packaged according to weight and customer requirements |

Delivery Time (Lead Time): | Samples in 7 days, cargo in 20 days, the time depends on the quantity the order. | FOB Port: | Shenzhen, or Guangzhou |

| MOQ: | 1 pcs | Payment: | T/T, Western Union, Paypal, L/C |

Material-JIS | Material-AISI | Hardness | Applications |

SKH-9 | M2 | 61-64 HRC | Used for cold forging die, punches, flat dies, punch pins, etc. |

SKH-55 | M35 | 63-66 HRC | Used for advanced screw dies etc. |

ASP-30 | M42 | 66-68 HRC | Used for making high-heavy-load dies, pins of powdered high-speed steel/ stainless steel screws, and punches of hollow rivets. |

Type | TiN | TiCN | TiAlN | CrN | WC/C | ALCRONA |

Hardness | Hv2000 | Hv3000 | Hv3000~Hv5000 | Hv1800 | Hv1400 | Hv3200 |

Surface roughness | 0.4 | 0.3~0.4 | 0.4 | 0.5 | 0.1 | 0.35 |

Layer thickness | 2-4 um | 2-4 um | 2-5 um | 3-6 um | 1-4 um | 2-4 um |

Coating color | gold | gray | dark purple | silver | black | dark purple |

Max working temperature | 550℃ | 400℃ | 850-1000℃ | 700℃ | 300℃ | 1100℃ |