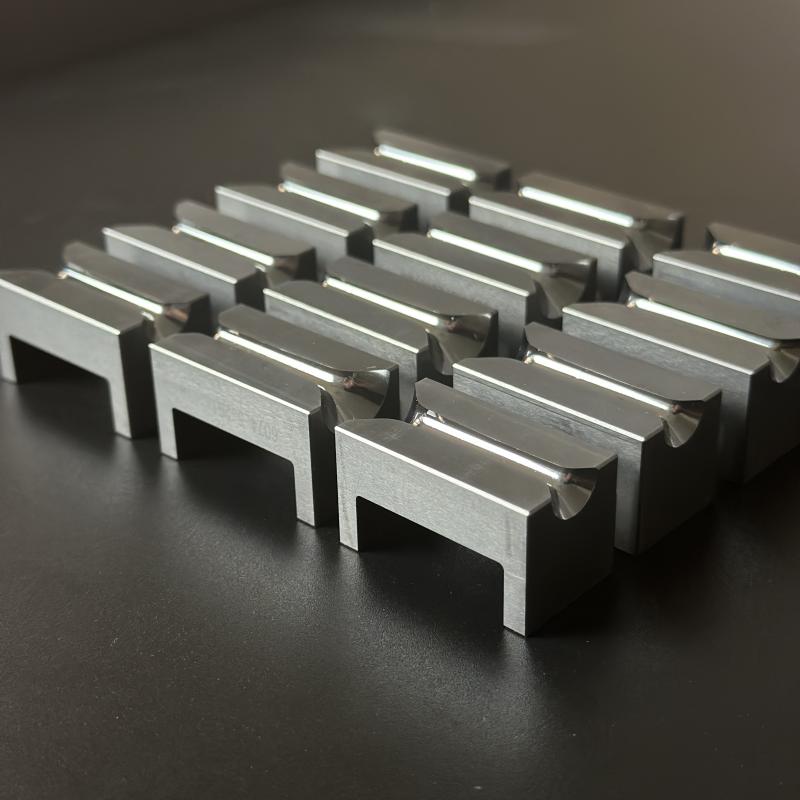

Three-Piece Collapsible Mold is a special mold used for injection molding. It consists of three parts: upper mold, lower mold and middle mold. This design allows part of the mold to be folded for easier removal from the molded part. Three-piece Collapsible Molds are often used to make parts with internal structures, such as holes or hollow sections. Its design can not only reduce damage to molded parts, but also improve production efficiency. This kind of mold is widely used in industries such as plastic products, medical equipment, and electronic products. It is especially suitable for producing complex parts that require internal structures, bringing convenience and efficiency to the production process.

Working Principle:

The working principle of the Three-Piece Collapsible Mold is based on its unique construction design. The mold consists of an upper mold, a lower mold, and an intermediate mold, which can be collapsed with either the upper or lower mold. During the injection molding process, the mold is first closed and the upper and lower molds are clamped together to fill the mold cavity with injected plastic. When the molding cycle is complete, the middle mold is folded, allowing a portion of the molded part to be easily removed from the mold without excessive force. This folding design greatly simplifies the process of removing the molded part, improves ease and safety of operation, and reduces damage to the molded part. This type of mold is suitable for the production of parts that require complex internal structures, bringing convenience and efficiency to the production process.

Features:

Flexibility: The mold design allows for partial folding, making removal from the molded part easier, improving operational flexibility and convenience.

Reduce damage: The folding design of the mold can reduce damage to the molded parts during the removal process and protect the integrity and quality of the product.

Wide applicability: Suitable for the production of parts that require internal structures, such as holes or hollow parts, meeting the molding needs of complex products.

Improve efficiency: The folding design reduces the difficulty of taking molds, speeds up the use cycle of molds, and improves production efficiency and capacity.

Reduce costs: Reduce product damage and mold replacement times, reduce production costs reduce production costs and improve production efficiency.

Precise molding: The three-piece structure ensures the stability and accuracy of the mold, ensuring the accuracy and consistency of the molded parts.

High reliability: After optimized design and strict testing, the stability and reliability of the mold are ensured, and it performs well in long-term production.

Wide range of applications: Suitable for plastic products, medical equipment, electronic products and other industries, providing effective solutions for the production of various complex parts.

Maintenance and care

Regular Cleaning:Regularly clean the molds to remove plastic residues and impurities in the mold cavities and to maintain the surface finish of the molds.

Checking wear and tear:Regularly check the parts of the mold, especially the wear and tear of the folding core, and replace the parts with serious wear and tear in time to ensure the normal use of the mold.

Lubrication:Regularly lubricate the movable parts of the mold to reduce friction and wear and prolong the service life of the mold.

Storage environment:The mold should be stored in a dry and ventilated environment to avoid moisture and corrosion and keep the performance of the mold stable.

Application Fields

Automotive Industry:In the automotive industry, Three-Piece Collapsible Mold is widely used to manufacture parts with complex geometric shapes, such as instrument panels, lamp housings and so on.

Home Appliances:Many parts in home appliances have complex internal structures, such as the inner tubes of washing machines, air ducts of air conditioners, etc. Three-Piece Collapsible Mold can meet these needs.

Medical Devices:Medical devices often require high precision and complex shaped parts, Three-Piece Collapsible Mold can provide high quality molding solutions to meet strict medical standards.

Consumer Electronics:In the consumer electronics field, many products such as cell phone cases, laptop cases, etc. require parts with complex structures and high quality appearance, and Three-Piece Collapsible Mold can provide the ideal molding solution.

FAQ:

How does the three-piece collapsible mold work?

The three-piece collapsible mold consists of upper mold, lower mold and middle mold. The middle mold can be folded with either the upper mold or the lower mold. During the injection molding process, the mold is closed and plastic is filled into the mold cavity. After molding, the middle mold folds so that part of the molded part can be easily removed from the mold.

In which industries are three-piece collapsible molds widely used?

three-piece collapsible molds are widely used in plastic products, medical devices, electronic products and other industries, and are especially suitable for the production of parts requiring complex internal structures.

What are the advantages of three-piece collapsible molds over traditional molds?

Compared with traditional molds, three-piece collapsible molds allow molded parts to be removed from the mold more easily, reducing damage and improving operational convenience.

What are the options for manufacturing materials for a three-piece collapsible mold?

The three-piece collapsible mold is usually made of high-quality tool steel or carbide to ensure the strength and wear resistance of the mold.

How to ensure the stability and safety of mold folding?

The folding design of the mold has been precisely calculated and rigorously tested to ensure stability and safety when folded to prevent accidents.

What types of product production is this mold suitable for?

Suitable for the production of products requiring complex internal structures, such as parts with holes or hollow parts.

What are the maintenance methods for three-piece collapsible molds?

Maintenance methods include regular cleaning, lubrication maintenance, regular inspection and regular maintenance to ensure the stability and performance of the mold.

What is the future development direction of three-piece collapsible mold technology?

Future development directions may include optimizing design, improving production efficiency and improving material technology to meet increasingly complex product production needs.

Three-Piece Collapsible Mold Product Information | |

Product Name | Three-Piece Collapsible Mold |

Brand Name | Donglong |

Place of Origin | Dongguan, Guangdong, China |

Specification | Customized on Request |

Customization | Material, size, shape, convex and concave marking, coating, laser engraving mark and packing are all customizable. |

Product Material | Carbide.ASP23 Vanadis.CPMRTXM4.SKD11SKD61HSSA2M2D2SUJ2.S45C.ect |

Standard | DIN ANSI BS JIS |

Tolerance | ±0.002mm |

Surface Treatment | TiCNTiN,Aitain,Ticrnnitriding Black oxygened Black coating etc available |

Polishness | Close to Ra0.2 Hardness Depends on material(HRC60~94) |

Hardness | Depends on material(HRC60~94) |

Shaping Mode | Grinding, wire cutting, EDM, cnc machining, cnc turning, cnc Milling |

Application | Machinery Parts and Molds |

Material for Core of Three-Piece Collapsible Mold | ||||||

Grade | WC+Other | Co | Grain Size | Density | Hardness | TRS |

(±0.5%) | (±0.5%) | (g/cm³) | (HRA)±0.5 | (N/mm²) | ||

KG5 | 88 | 12 | Medium | 14.31 | 88.3 | 340 |

KG6 | 86 | 14 | Medium | 14.12 | 87.3 | 320 |

EA65 | 82 | 18 | Coarse | 13.75 | 85 | 300 |

EA90 | 76 | 24 | Coarse | 13.22 | 82.8 | 270 |

ST6 | 85 | 15 | Coarse | 13.8 | 86 | 270 |

ST7 | 80 | 20 | Coarse | 13.4 | 85.3 | 270 |

VA80 | 80 | 20 | Coarse | 13.58 | 84 | 280 |

VA90 | 78 | 22 | Coarse | 13.39 | 82.5 | 240 |

VA95 | 75 | 25 | Coarse | 13.12 | 81.5 | 220 |

Material for Casing of Three-Piece Collapsible Mold | |||

Material | Hardness (HRC) | Features | Applications |

H13 | 59-61 | H13 is a chromium molybdenum hot work steel with exceptional hot hardness and abrasion resistance, general hardness, and toughness. | Used for extrusion dies, forging dies, stamping tools, etc. |

SKD11 | 58-61 | SKD11 tool steel has good wear resistance and size ability after heat treatment. | Used for tensile dies, cold extrusion dies, first punch holder, etc. |

SKD61 | 43-53 | SKD61 steel is a high-grade die casting die. It has heat shock resistance, heat deformation resistance, heat fatigue resistance. | Used for heat work dies, cold heading dies, second punch holders. |