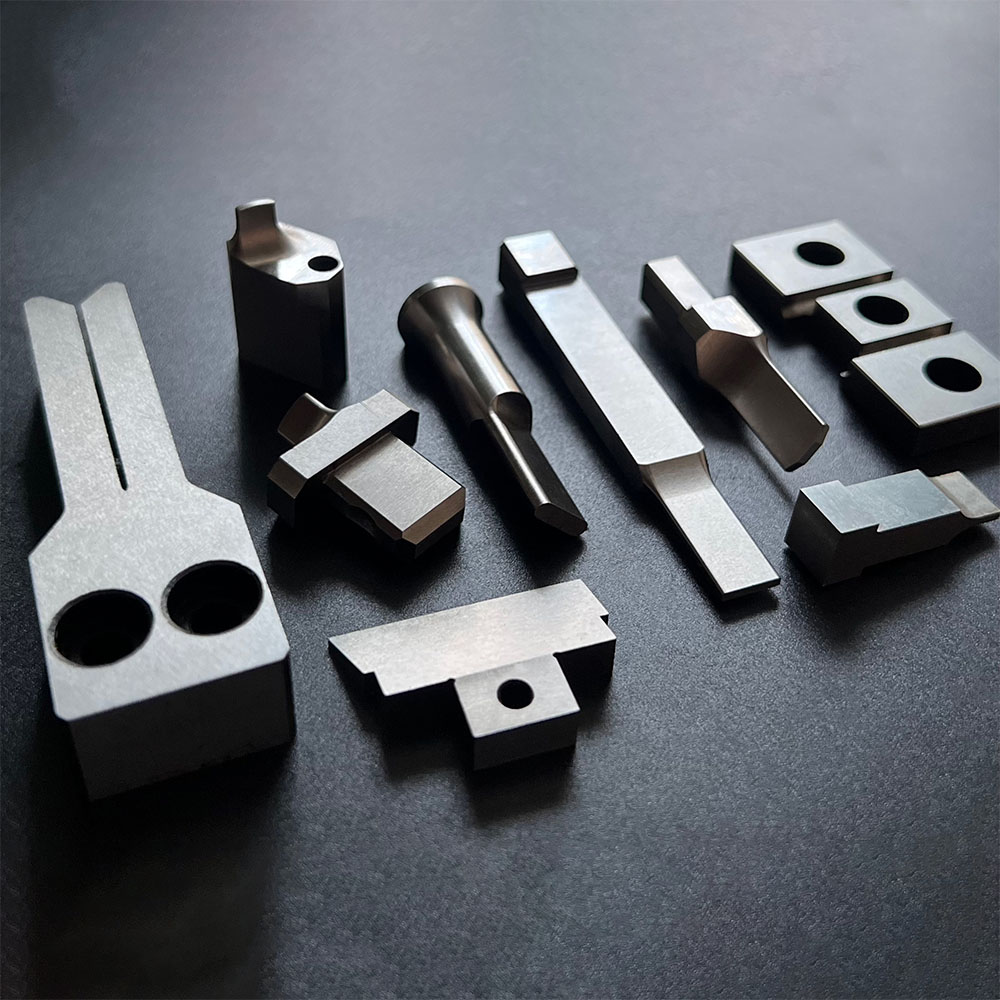

Transfer Fingers play a crucial role in the performance and reliability of Cold Heading machines. As a key component in the workpiece transfer process, the condition of the Transfer Finger for cold heading machine directly impacts production efficiency, dimensional accuracy, and equipment longevity. To prevent unexpected downtime and ensure optimal operation, implementing a robust maintenance strategy is essential.

Below are several practical maintenance tips designed to extend the service life of your cold heading transfer fingers, whether they are OEM or custom transfer fingers for special applications.

1. Daily Cleaning to Remove Debris and Metal Shavings

Cold forming and cold forging machine transfer tools operate in high-speed, high-friction environments. Metal chips, lubrication residues, and other debris can accumulate on the transfer mechanism for cold header, especially around the transfer finger. Daily cleaning using a non-abrasive brush and lint-free cloth helps prevent buildup that could hinder finger movement or cause alignment issues.

Tip: Use compressed air carefully to dislodge debris without driving it deeper into the mechanism.

2. Lubrication: The Key to Smooth Transfer Motion

Just like other Cold Heading Tooling parts, the transfer finger requires adequate lubrication to function correctly. Lack of lubrication can increase friction, accelerate wear, and even lead to seizing during continuous operation. Use a high-quality lubricant suitable for cold heading equipment accessories, especially in high-speed or high-load settings.

Recommended Frequency: Apply lubrication at the start of every shift or after every 8-12 hours of operation, depending on your production cycle.

3. Regular Visual and Functional Inspections

Even the most durable high precision cold forming fingers will degrade over time. It is recommended to schedule regular inspections to check for:

Surface cracks or deformation

Uneven wear or thinning edges

Looseness in the mounting slot

Alignment issues during transfer

These checks should be integrated into your overall cold header maintenance program and recorded for future reference.

4. Monitor Transfer Accuracy and Adjust as Needed

The primary function of a cold heading machine transfer finger is to ensure precise, reliable workpiece movement between forming stations. If you notice inconsistent part alignment, misfeeds, or increased rejection rates, it may signal that the transfer finger is worn or misaligned. Prompt realignment or replacement can help maintain productivity.

Pro tip: Use test samples at the start of each production batch to confirm transfer accuracy.

5. Replacement Cycle: Know When It's Time

Even high durability, wear-resistant transfer fingers have a finite lifespan. Depending on production volume and machine type, most transfer fingers need replacement every 3 to 12 months. Waiting until failure can lead to costly production halts or damage to other cold header finger components.

Set a proactive replacement schedule based on:

Material used (e.g., heat-treated alloy steel vs. standard carbon steel)

Hours of use

Environmental conditions (e.g., exposure to high temperatures, corrosive oils)

6. Use Quality Parts: OEM vs Aftermarket Considerations

When sourcing replacement transfer fingers for cold heading machines, it’s crucial to choose components that match the quality and tolerance of the original. OEM transfer fingers guarantee compatibility, while aftermarket transfer fingers may offer cost advantages but vary in quality.

Tip: For high-speed cold header parts, prioritize precision-machined components with verified test reports or material certificates.

7. Storage and Handling Best Practices

Store spare transfer fingers in clean, dry environments to prevent corrosion or mechanical damage. When handling, avoid dropping or over-tightening during installation to maintain the integrity of the finger-type transfer system.

By following a disciplined maintenance routine—including regular cleaning, proper lubrication, scheduled inspections, and timely replacement—you can dramatically improve the performance and lifespan of your transfer fingers for cold heading machines. High-quality maintenance not only protects your investment in cold heading equipment but also supports continuous and efficient fastener manufacturing.